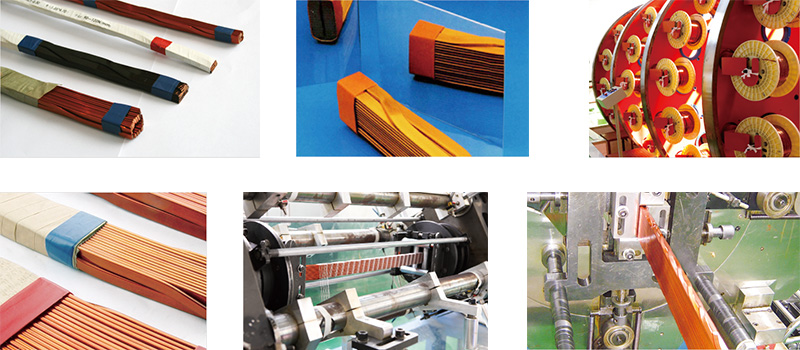

Product Introduction

Continuously transposed conductor (CTC) is a type of touched two lines winding wire which combined with certain number of rectangular enameled strips, request both upside and downside of two lines of enameled strips transposed as one direction, and continuously wrapped insulation paper, rope or belt.

Mainly have application in power transformer, traction transformer and reactor. The biggest characteristics of CTC is using hard wire or epoxy wire or both of these condition in a wire, this kind of wire have more mechanical strength, increase resistance to short-circuit for coil, able to keep coil power and voltage stable for long time and decrease whirlpool of winding and circulation current loss, compare with other copper wire. effectively improve useful rate of winding space, decreasesize of transformer, save transformer oil, improve winding efficiency

Manufacturing Scope

Number of single conductor:5-79(odd number)

Individual conductor dimension:

Conductor thickness,a:1.12-3.00mm Width,b:3.00-12.50mm

Suggested width/thickness of single conductor:2.5<b/a<7.5

lf your required dimension out of abovescope, please contact with us.

Product Type

PVA half hard enameled with paper insulation CTC

PVA half hard epoxy enameled with paper insulation CTC

PVA epoxy enameled with netting insulation CTC

Aromatic polyamide paper insulation 180 class ElW enameled half hard CTC

Polyester fibre, non-weaving belt insulation 155 class PEW enameled half hard CTC

Material

| Type of enameled wire | Type of insulating enamel | Thickness class | Enamelincrease (not including epoxy) | Epoxythickness mm |

enameled iat wire (notrcluding epoxy) | Polyvinyl acetal resin + (epoxy resin) | 1 | 0.1±0.02 | 0.03-0.05 |

| 2 | 0.15±0.04 | 0.03-0.05 |

EIW enameled flat wire(incuding epoxy) | EIW resin +

(epoxy resin) | 1 | 0.11±0.02 | 0.03-0.05 |

| 2 | 0.15±0.04 | 0.03-0.05 |

200 class AIW/EIW enameled flat copper wire | EIW +PLA resin or + epoxy resin | 1 | 0.11±0.02 | 0.03-0.05 |

| 2 | 0.15±0.04 | 0.03-0.05 |

According to different mechanical strengthrequirements,half-hard cooper conduct property index in following table

| Type | Provisions non-proportional extension intensity | Min.elongation/% | Max.resistivity at 20℃ / (Ω·mm2/m) |

| Anneal copper | 60-100

| 32 | 1/58.0 |

| CuAgO.1 | test achieve value | 15 | 1/57.5 |

| C1 | 101-180 | 20 | 1/58.0 |

| C2 | 181-200 | 20 | 1/57.5 |

| 201-220 | 15 | 1/57.5 |

| C3 | 221-260 | 15 | 1/57.0 |

WrappedInsulation Material

Insulation Material Type | Recommend Thickness | Application On | Main Properties |

Normal High Density Paper | 0.075-0.125 | General purpose |

|

lmported High Density Paper | 0.060-0.075 | General purpose | High density and high dielectric strength, low ash |

Domestic Thermally Upgrade Paper | 0.05-0.075 | General purpose | Heat resistance

|

lmported Thermally Upgrade Paper | 0.065-0.105 | General purpose | Heat resistance |

| Epoxy Coating Kraft | 0.080-0.130 | Inner Layer Or Outermost Layer | Adhesive property

|

Aromatic Polyamide Paper | 0.05-0.08 | Temperature class 200

| thermostability |

| Thin Film | 0.05 | Gas insulated transformer |

|

| Alkali-Free Glass Fibre | 0.08-0.10 | Dry-typetransformer

|

|

Polyester Netting Ribbon | 0.28 | CTC without insulation paper or reinforce insulation for a certain part | Good cooling performance |